VideoHere is a video of the Cleanblend blender in action:

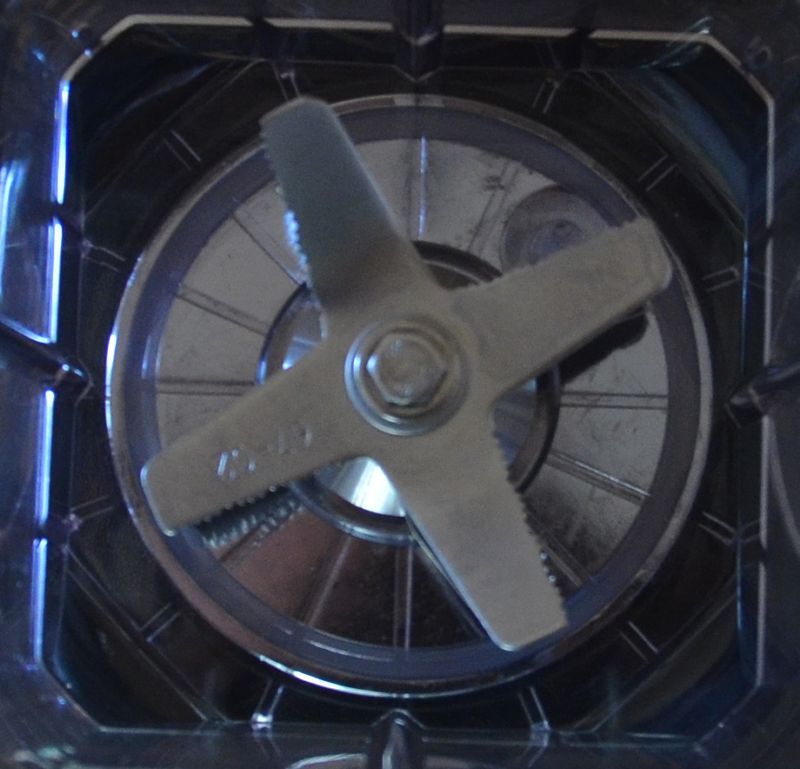

PhotosHere are some pictures of our Cleanblend blender:

Cleanblend blender - container and base

The blender costs about half of many of its competitors - a definite plus point. There are some corresponding down-sides - the manufacturer does not appear to be well known - and spares and repairs may be harder to come by. I haven't had a blender break on me yet, though. I don't much like plastic/polycarbonate containers. They get scratched up and become more difficult to clean. Manufacturers use them to avoid consumers smashing their glass containers and cutting themselves. I am not very worried about that - but I am concerned about bacteria living in a scratched plastic containers. I'll see how this container stands up. The claimed "1800 watts" is equal to 2.4 HP. Putting 3 H.P. on the front of the machine - perhaps on the grounds that that is the specification of the motor - seems a little misleading. The manufacturer claims 1800 watts and 38,000 RPM unloaded. So far the motor has worked well enough for me. This blender is significantly more powerful than machines I have previously used. The motor is probably a blender's most important feature. This motor would benefit from being independently tested - to see how much current it actually draws when in use. Having said that, rating blender motors by how much power they can draw seems pretty silly to me - that just encourages the use of inefficient motors. This motor seems fairly light. It fairly often has difficulty in spinning up - i.e. it gets stuck. It is slowed substantially by thick liquids. It seems powerful enough for most blending tasks - but the high horsepower rating should probably be taken as being fictional marketing spiel. The motor in this machine exhibited a "burning rubber" smell the first few times we used it. Many wound motors do this - as the plastic on the motor winding "cures". However, some consumers might panic and return the machine if this happens. Perhaps the motors in these kinds of machines should come "pre-cured". Good produce circulation helps blenders to process all of their contents completely. Circulation in this machine is probably good enough. Blades that disturb the body of the fluid more could probably be used to increase circulation. The blade design can help to apply more force to the liquid. Instead of bending the blades straight up (and down), they should probably be bent at an angle. This machine does do exactly that, but only with two of its six blades - and only a little. Maybe shaping the trailing edge of the blades would help with this issue too. However, increased circulation might also result in increased levels of Blender cavitation (see below). I also think you also want more curves in the bottom of the container - to help the downward-impelled liquid to have a smooth curved path up around the sides of the blades - instead of slamming into the bottom and sides of the container - and losing kinetic energy in the process. The bottom of the container should probably be shaped rather like half a bagel. The blades in this machine are serrated. Serration does helps with some cutting tasks - but it isn't clear to me that they help very much in a blender. It seems unnecessary - and probably makes the blades harder to manufacture and sharpen. Of the six blades in this machine, two are thinner and not serrated. Overall, I think I would prefer an even simpler arrangement - with four identical blades, bent up and down alternately. Or maybe two sets of three blades would work well - though this might be more costly to manufacture. Blender cavitation is a common problem for many high-powered blenders. This machine frequently exhibits cavitation - and it's not very pretty. The weapons against cavitation include inserting the tamper, using the tamper, adding more water, filling up the container further, using slower speeds and stopping and starting the blender. This machine is pretty noisy. I understand that this is a common feature of powerful blenders. This machine is generally aesthetically pleasing. The housing is made of plastic, though. I would prefer my kitchen appliances to be white - not black - so that they more easily show up any dirt that gets on them. The rubber lid works pretty well, but it is a tiny bit awkward to seal on completely. This isn't a huge deal. The little rubber feet on the base are rather small. As a result, the blender can sometimes migrate around on the surface it is on. Bigger feet would probably help with this minor issue. The shape of the container's spout is sub-optimal. It tends to cause smoothie to drip down the outside of the container - unless you pour very slowly. It would be possible to do quite a bit better within the same general form factor by simply changing the shape. However, this is a pretty minor issue. The container seems be be made from a reasonably high quality material which is pretty scratch resistant. After several months of use it appears to be as good as new. It looks as though it will last for quite a while. The design of this machine appears to be very similar to the design of Vitamix blenders. Those appear to be well-designed machines - which are well worth imitating. If Vitamix containers do indeed fit on the Cleanblend base (as appears likely), then that would be a potentially-useful feature of the machine - meaning there's an abundant supply of spare parts. Spare containers appear to be available from both Vitamix and Blendtec. The machine has no significant safety features. In other words, the drive socket can be powered without the jug being on the base. This might help a little with container compatibilty between machines. The jug features a removable blade. The base features a removable drive socket. I haven't tried removing the blade, but I can see the bolt involved. The drive socket comes off easily. THe screw involved can need tightening from time to time. Competition for the machine comes from other Vitamix-like machines - such as the Oster Versa. That machine also features a Vitamix-compatible spindle. It has a longer warranty. However it currently seems to cost more. I notice that the blade seems to be essentially the same as the one used in the JTC OmniBlend blenders (particularly the OmniBlend I). Also the base units look very similar from beneath.These machines appear to be closely related. The JTC Omniblend claims "2,238 Watts (3HP) / 950 Watts (max workpower for machine longevity)". Overall, so far, this seems like a pretty good machine for the money.

2018 updateThe blender is still going, four years on. However, the jug started to suffer from corosion on the base. I decided to buy another one from Cleanblend. I paid 90 USD for it. Photos follow:

Cleanblend blender - new jug and old jug

I thought about buying a Vitamix jug but decided against it - too risky. The new jug is quieter than the old one. It has 8 blades - there are two new sticky-up ones. The jug works better than the old one. It fits under my counter a little bit better. The only problem is that the blade is much stiffer to turn - which could be a bad sign. After a few weeks it has not loosened up with use - but it hasn't got any worse either. These are sealed bearings - and perhaps this is just how they are.

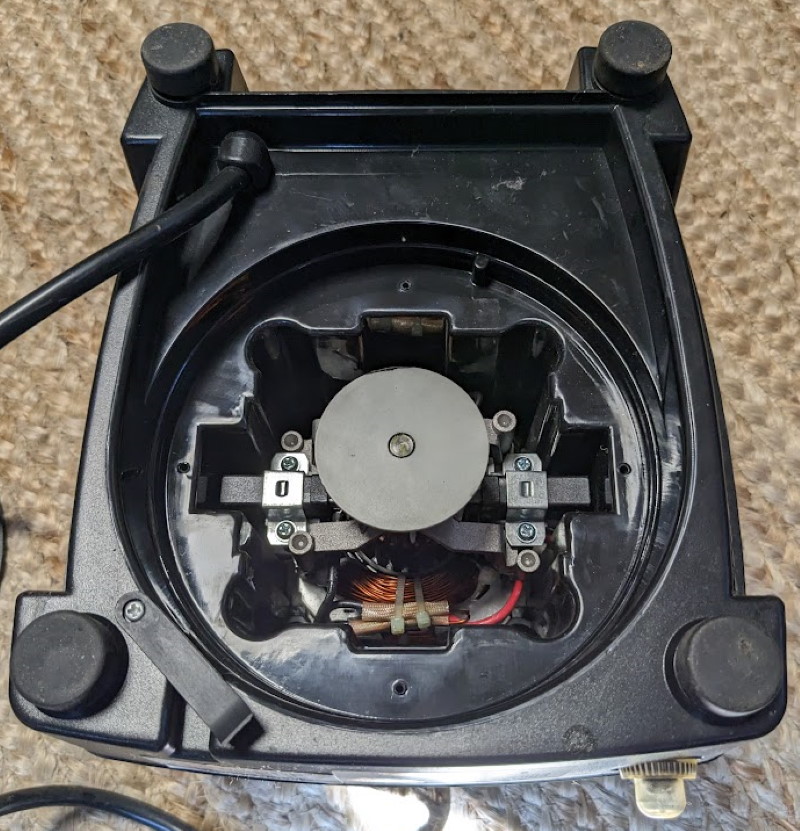

2023 updateI replaced my Cleanblend blender in March 2023. The motor unit was still fine. However the bearings in the blade assembly had clearly suffered aging damage. The blade had become very stiff to turn and made a lot of noise when the machine was in operation. My wife complained that the machine smelled when in use. Rather than replace the blade, I bought a whole new blender.I did disassemble the pitcher to make sure I could access the blade assembly - in case I ever did decide to perform repairs. The pitcher was a little scratched up and the rubber lid had accumulated some surface damage that made it harder to clean, but the pitcher is still usable - apart from the blade. I also attempted to disassemble the original pitcher that came with the machine. That proved impossible. The blade and the retaining nut had fused together - and they turned together when I attempted to unscrew them. There was nowhere to apply a wrench inside the pitcher. I trashed the whole thing. I also took off the base and took this picture of the motor:

Cleanblend motor

References

|