|

If all the parties involved were to get together, they might collectively produce a great machine. There are several good ideas in the Twin Health machine: As a result of the screens that splits in a horizontally into two pieces, there are all sorts of design possibilities for dividing the region inside the screens into different chambers. The gears on the machine actually have two grooves on them - as though they are designed to create three separate chambers. There is even a divider partially blocking off one of the chambers. I think this is an idea with great potential. It could be used to address several problems with the machine. One such problem involves cutting long fibres: Many juicers have problems with very fibrous produce. The Twin Health lacks sharp cutting blades in its grating section, and has no notches in its gears designed to help cut long fibres. I suspect these problems contributed to the "rhubarb" machine jam I experienced with the machine. Creating disturbances in the path of produce through the machine - in the form of partial barriers between chambers - might help resolve this problem. Another historical problem with twin gear machines is that only the area of the screens near the pressure regulator tends to get used - since only there is sufficient pressure built up. Separate chambers within the screen housing could help with this problem - if this involved additional pressure regulators. These could then be graduated in strength through several chambers making more use of the earlier screens. Putting more physical barriers in the machine might increase the tendency for produce to "back up", though - and block the feeding chute. Simple suggestion My first simple suggestion for modifications to the Twin Health machine would be to modify the screen "ceiling" - by putting in barriers - as follows:

Gear changes Next I would try changing the screw section of the gears so there was less empty space.

I figure there should be about 49% stainless steel - and 51% empty space in this area. The Samson Ultra gets the design about right here. If all that space was eliminated, there would not be so much space for this sort of thing to happen:

The next-most important thing would probably be narrower gears. Twin gear dreams What would my dream machine look like? I have a few ideas... I'd like to see all-stainless-steel gears divided into sections as follows:

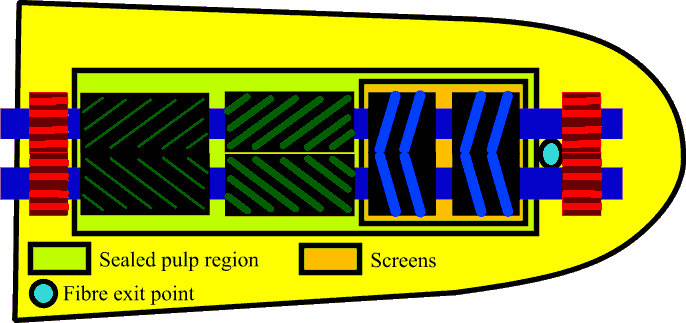

Gears The "Cogs" would be the only parts in contact with one another. They would be sealed outside the region where the pulp was. Looking at the current twin health assembly:

...a rearrangement occurs to me: I think the part on the left could be completely dispensed with. The current screen roof could expand to the left to include the existing feed chute. The current screen floor could expand to the left by an equal ammount. The result would be an expansion of the two existing screens so that they completely encased the gears.

Plan view of bottom section with screens

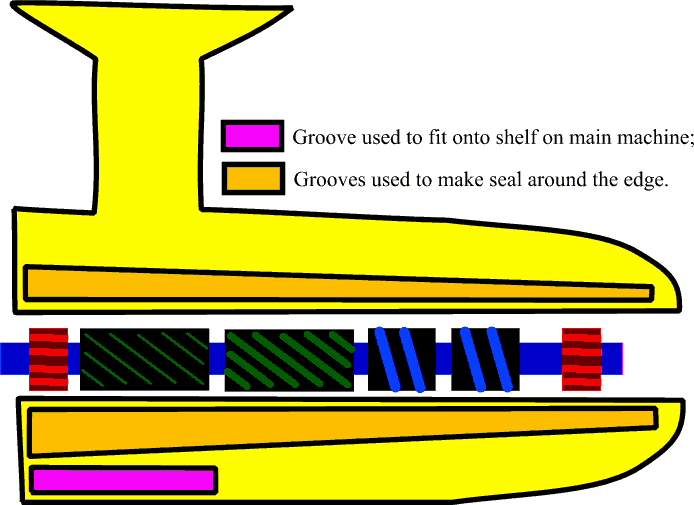

View from the side The main difficulty with this proposal it that it leaves a big - and potentially-leaky - horizontal seal all around the edge of the "sealed pulp" section of the juicer. I think making a reasonable seal there would be a soluble problem.

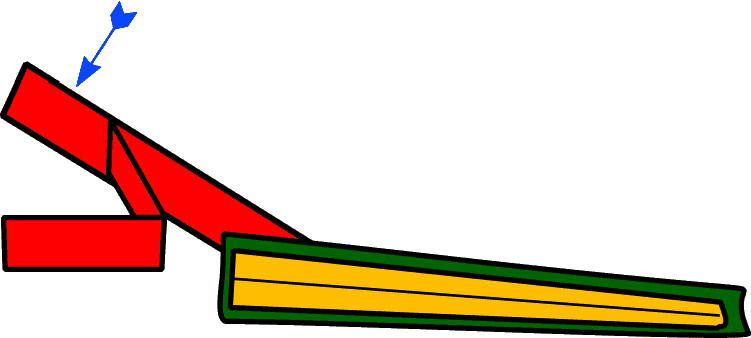

Side catch Catches of the following shape, attached to the side of the machine could be made to exert significant force along most of the perimeter of the seal - if force were applied in the direction indicated by the arrow. Many suitcase catches work in a similar way. They can reach out a little, and then be drawn back again with force by using a lever principle. Assembly would consist of placing the gears onto the bottom tray with the screens, sliding that horizontally onto the shelf on the body of the machine, placing the top section (with the chute) on from above - and then sealing everything in place using the edge catches. The catches act as levers - which translate force applied horizontally into a larger force between the orange sections - which squeeze the components together. The bottom section (the one with the screens) would contain Twin Health-style pressure regulators. Any rubber seals would be attached to the top component. The illustrated catches would probably make a reasonably- impenetrable physical barrier along both sides of the machine. Some material might leak out around the gear holes at either end - but that probably won't be a big problem - pulp is expected to emerge at one end - and at the other end pulp is under very little pressure. The regions at either end where the cogs are should be isolated and drained - so that any escaping pulp does not interfere with their opearation. Advantages Though somewhat less modular, this system would reduce the component count - and would result in less things needing washing. Also, it would properly separating the twin gears - without being reduced to using nylon parts.

|