|

Blenders The blender was one of the first mechanical digestive aids. The basic design has remained: a powerful motor with stainless-steel blades that spin within a glass goblet. Blenders vs juicers Here I will attempt a brief comparison with my twin gear juicer. Advantages to using a blender:

However - my subjective impression is that blending produces a grossly inferior output compared to a twin gear juicer. I don't know exactly where most damage is done by blending - but can testify that the resulting product appears to measure up poorly to the output of my low-RPM juicer. I would love to see some scientific studies investigating the relative effects of blending, juicing and chewing produce on the lifespan of organisms - or on other health-related variables. Rapid oxidation is not inevitable There is one area where I feel blenders could probably have the quality of their juice improved. It seems to me that it should be possible to reduce the extent to which air is stirred into the juice, under some circumstances. Currently - in most blenders - a vortex is created spins the produce against the outer wall - and that propels air down onto the rotating blades. Many blenders attempt slow down the rotating juice and to reduce the presence of the vortex (by introducing turbulence) - but I feel their efforts could be improved upon a great deal. It may be possible to largely eliminate the air vortex under some conditions. To give some examples of the sort of design I think might help, here are some diagrams:

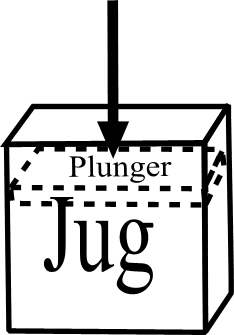

This diagram is intended to illustrate operation where the produce is covered with water, and then a plunger descends from above - excluding all air from the blending chamber before operation commences. The plunger winds up being covered by a thin layer of water, which seeps through the narrow gap around the edge of the plunger. This should prevent air from being stirred into the juice - and consequently oxidation would be minimised.

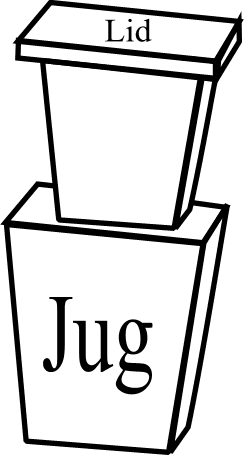

The design might mean that produce needs more initial chopping up - so it doesn't get trapped between the walls. Care would need to be taken with the design so that produce is not kept away from the blades by the lid protrusion. The protrusion from the lid might mean any ceiling chute is best displaced sideways. Clover leaf Waring once trademarked a clover-leaf design for their carafe. The clover-leaf shape appears to be effective at preventing the liquid from sloshing around with the blades. Åke Brännström's idea Åke Brännström suggested to me that filling the blender with a relatively inert gas - like nitrogen or carbon dioxide - would be effective at reducing oxidation. This idea seems interesting and relatively easy to test - but I have not yet looked into the issue. My blender's design I'll only briefly discuss my blender's design - since I believe the 3901 model I own is no longer being produced. I bought the most powerful blender I could find at a "reasonable" price. This is a 550 Watt blender. My perception is that significantly more power would be desirable. The blender is basically very good. It has a 1.5L glass goblet, and three speed control. My main complaint is that the goblet's base seems to be fused on - so replacement is an all-or-nothing affair. Another niggle is that the blender can't easily be shaken while in use - since the goblet does not lock onto the base. Shaking can force foods down onto the blades by using their inertia. Performing this operation is probably done at some cost in terms of safety, and wear and tear on the motor, though. I don't much like the rubbery lid - but it seems to do its job well enough. I feel that a better job could be done in preventing liquid from rotating in the goblet along with the blades. The safety feature prevents operation when the goblet is not present - but makes no effort to prevent operation when the lid is not in place. This is probably a sensible design decision for a machine with a glass goblet - but it means that there is room for improvement on the safety front. Price This machine cost me £30. I bought it on [eBay].

Suppliers

|